Paintsville training facility opens robotics center

Greg Smith, president of Teradyne, addressed guests at the eKentucky Advanced Manufacturing Institute (eKAMI) Robotics Center grand opening Friday in Paintsville.

Kentucky Energy and Environment Secretary Rebecca Goodman greeted eKAMI students at Friday’s grand opening.

By TONY FYFFE

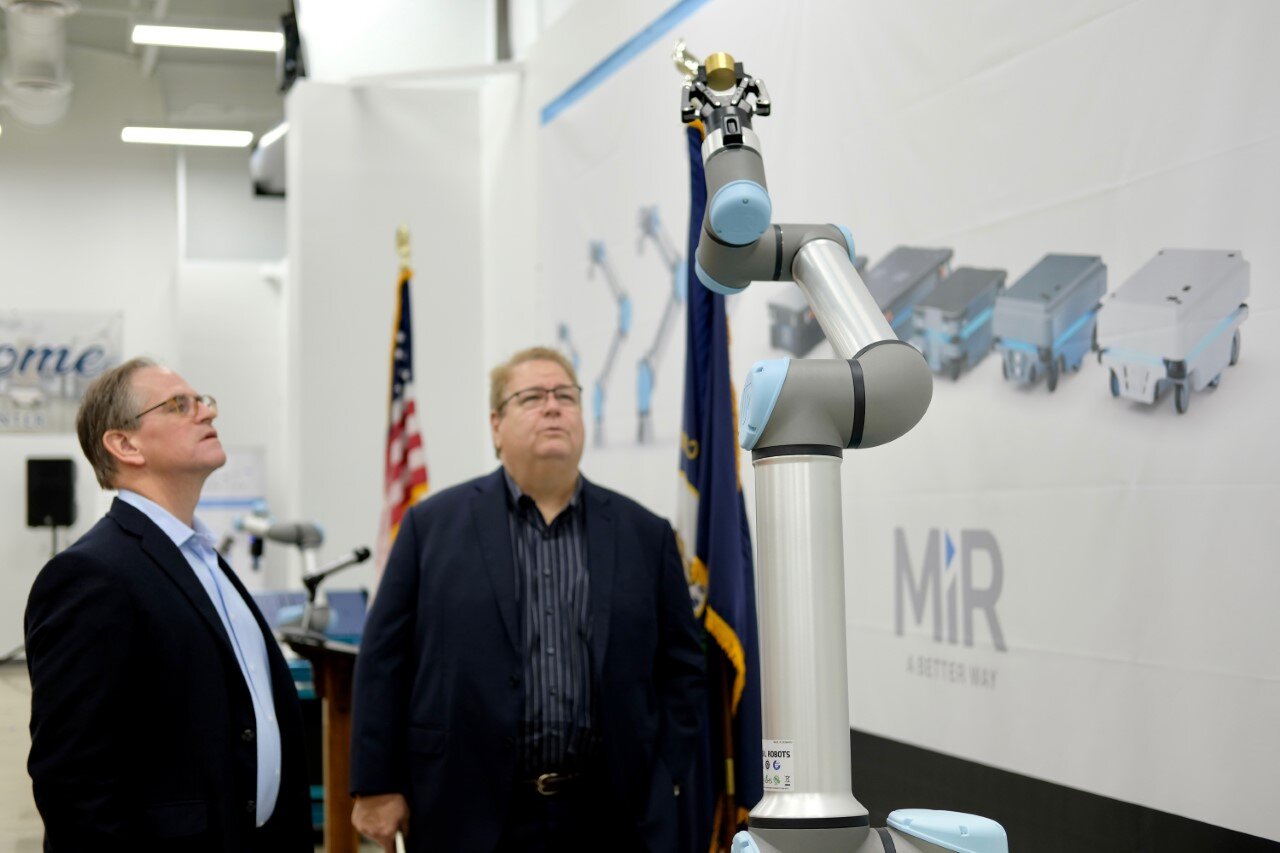

Greg Smith (left), president of Teradyne, and Tim Moriarty, president of AutoGuide Mobile Robots, looked at one of the robots at the eKentucky Advanced Manufacturing Institute Robotics Center Friday.

BSN Editor

PAINTSVILLE – The eKentucky Advanced Manufacturing Institute Robotics Center officially opened Friday with a celebration attended by invited representatives from both industry and government.

The center will be home to both mobile and fixed robots from companies such as Teradyne’s AutoGuide Mobile Robots, MIR (Mobile Industrial Robots) and UR (Universal Robots) divisions and Yaskawa Motoman.

The new facility will allow eKAMI students to receive hands-on training with robots that are used daily in manufacturing and logistics facilities across the world.

“We are excited to open this new chapter in the eKAMI story,” eKAMI founder and CEO Kathy Walker said. “This expansion provides additional cutting-edge skills which are in high demand by employers. To deploy automation, more companies are looking for individuals with a basic understanding of robotics. eKAMI will be able to assist with this transition by providing a new workforce skilled in this area.”

The new center has the support of many companies that operate in robotics and automation space, with many of them providing robots, software, services, and accessories, according to Walker.

Sponsors and supporters of the new Center include Teradyne, owner of Universal Robots (UR), Mobile Industrial Robots (MiR), and AutoGuide Mobile Robots; Heartland Automation; Yaskawa Motoman; Ohmni Labs; READY Robotics; ROEQ; Robotiq; Vention; FedEx; and Appalachian Wireless

A recent study by Deloitte and The Manufacturing Institute found that the growing U.S. manufacturing skills gap could leave as many as 2.1 million jobs unfilled.

“This in-turn could result in a $1 Trillion hit to the U.S. economy,” a press release from eKAMI said. “Programs like eKAMI have been nationally recognized for addressing the skills gap by providing students with training in areas that employers need. While enrolled in the program, eKAMI students earn national credentials from the National Institute of Metalworking Skills (NIMS).”

Ben Gibbs, CEO of READY Robotics, said his company is “excited about our robotics contribution to eKAMI’s curriculum, and we’re excited to build on these efforts in a way that can solve the skilled labor shortage at scale and enable every U.S. manufacturer to easily deploy automation.”

READY, an early supporter of eKAMI’s efforts to add robotics to its curriculum, has already worked with three of the class cohorts, taking them from zero robot knowledge to doing light’s out production runs using the robots, the press release said.

“Our students were already in high demand by employers due to their advanced training in CNC machining,” Walker said. “Adding robotics to the curriculum is the natural next step in our goal of developing the skills needed to attract more manufacturers to Eastern Kentucky.”

Many eKAMI students have been hired as robot technicians by firms such as Heartland Automation and AutoGuide Mobile Robots.